Fully automatic ultra clean vacuum sintering and quality monitoring system (Hastelloy oxygen free well furnace)

Release time: 2025-11-05 18:15:06 Number of views: 13

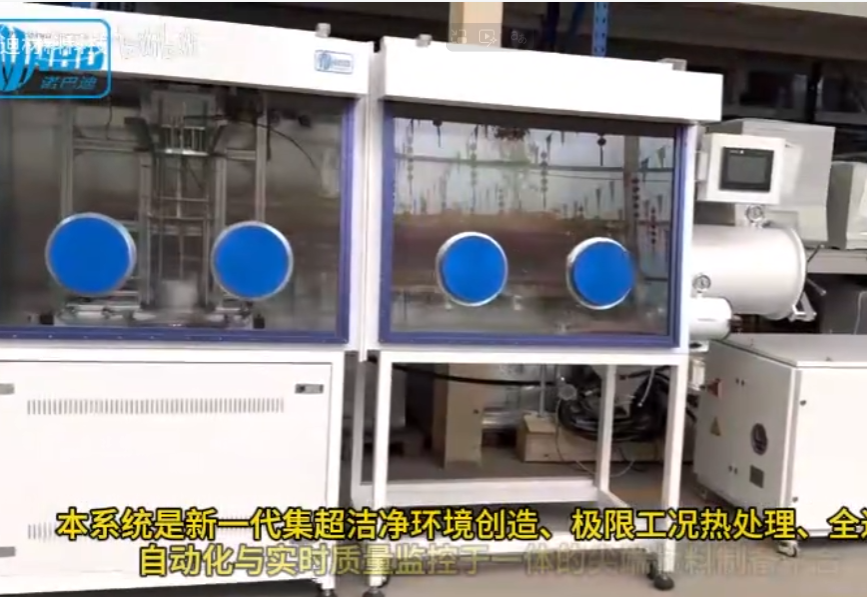

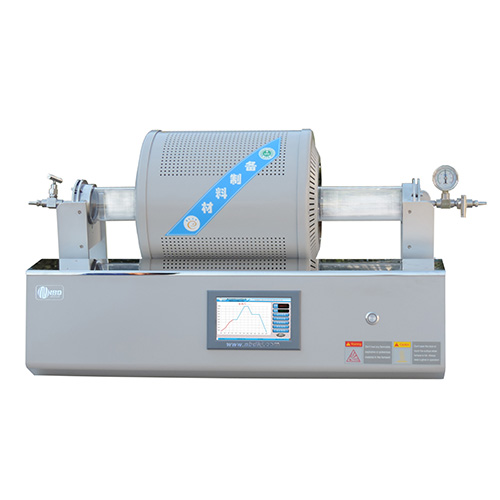

This system is a cutting-edge material preparation platform that integrates ultra clean environment creation, extreme working condition heat treatment, full process automation, and real-time quality monitoring. It has built a complete and traceable R&D and production loop by systematically integrating high sealed glove boxes, programmable vacuum/atmosphere well furnaces, automatic lifting mechanisms, and online oxygen content analyzers. This system not only provides full cycle oxygen free protection from pretreatment, sintering to cooling for materials that are extremely sensitive to oxygen/moisture, but also ensures extreme consistency of each batch process and ultra-high performance of products through real-time monitoring of key quality indicators (oxygen content). It is the ultimate solution for achieving "zero oxidation" preparation and intelligent production of high-end materials.

| Equipment Features:

| |

Device Name | Fully automatic ultra clean vacuum sintering and quality monitoring system (Hastelloy oxygen free well furnace) | |

Specification Model | NBD-PG1200-20TI5LN | |

power supply | AC380V 50HZ | |

rated power | 13KW | |

sensor type | K-type thermocouple Φ 2*350mm | |

Tmax | 1200℃ | |

Long term working temperature | 1150℃ | |

Recommended heating rate | ≤10℃/min | |

Number of temperature zones | Single temperature and single control | |

Size of furnace temperature zone | Φ350*420mm | |

Reactor material and size | Hastelloy C276

| |

One way float flowmeter | 0.3-3L/min | |

Exhaust method | Electric ball valve KF25 interface, vacuum port KF25 | |

Maximum stroke of lifting device | 650mm | |

furnace body dimensions | Glove box and furnace section: length 3500 * height 1985 * depth 910mm

| |

control system | | 1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

|

Hastelloy reaction chamber |   | Hastelloy is a high-performance nickel based corrosion-resistant alloy with nickel as the matrix and added elements such as molybdenum, chromium, and iron, widely used in extreme corrosive environments. Use it as a reaction chamber under high temperature, high pressure, and strong corrosive atmosphere. |

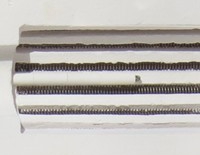

heating element |

| Alloy resistance wire |

temperature accuracy | ±1℃ | |

Net weight | About 950KG | |

Equipment usage precautions |

Untrained personnel are not allowed to use glove boxes without authorization; | |

Service Support | One year limited warranty, providing lifetime support (the warranty does not include consumable parts such as processing tubes and O-rings, please order replacement parts at the relevant product below) | |

·Cutting edge semiconductors and metal materials: highly oxygen sensitive perovskite, GaN, OLED materials, as well as high-purity heat treatment of titanium alloys, high-temperature alloys, and amorphous alloys.

·Frontier scientific research: Preparation and physical properties of superconducting materials, topological insulators, quantum materials, etc. in extremely pure environments, with oxygen analysis data providing key support for the conclusions of the paper.

·High reliability component manufacturing: oxygen free packaging and annealing of magnetic components and ceramic packaging for aerospace and military industries.

推荐产品

Pressure rotary tube furnace

Slide rail rapid annealing furnace

air blast drying oven

Vertical five sided heating furnace 1200 ℃

electric tablet machine

Microwave high temp muffle furnace

Open Mini Rotary Stove

FBCVD fluidized bed tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China