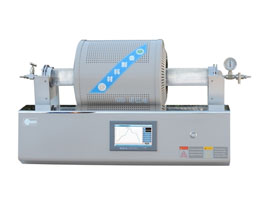

Integrated high-temperature atmosphere reaction and quenching treatment system

Release time: 2025-11-08 21:53:33 Number of views: 11

This system is a high-end laboratory comprehensive platform that integrates high-temperature reaction, rapid quenching (rapid cooling), precise gas distribution, online safety monitoring, and active exhaust gas purification. It innovatively integrates a quenching module on the basis of a standard atmosphere tube furnace, enabling researchers to complete high-temperature synthesis or heat treatment of materials in a precisely controlled atmosphere, and immediately cool them rapidly, thereby "freezing" high-temperature phases, regulating the microstructure of materials, and obtaining specific properties. This system is particularly suitable for studying phase transition processes, synthesizing metastable materials, and providing a comprehensive safety solution for handling high-risk gases such as carbon monoxide and carbon dioxide.

|

Equipment Features:

|

|

|

Device Name |

High temperature reduction or oxidation vertical tube furnace |

|

|

Specification Model |

NBD-LT1700-60TID3ZY10LW-N |

|

|

power supply |

380V 50HZ |

|

|

rated power |

10KW |

|

|

temperature control accuracy |

±1℃ |

|

|

sensor type |

B-type thermocouple with a diameter of 8 * 150mm |

|

|

Tmax |

1700℃ |

|

|

rated temperature |

1650℃ |

|

|

Recommended heating rate |

≤10℃/min |

|

|

Size of furnace temperature zone |

Single temperature control, temperature zone length 400mm |

|

|

Furnace tube specifications |

Corundum pipe with a diameter of 60 * 1100mm |

|

|

Intake method |

3-channel mass flow meter (nitrogen calibration):

|

|

|

Inlet specifications |

Φ 6.35 double card sleeve |

|

|

Draw true blank specifications |

KF16 interface |

|

|

vacuum pump |

Extraction rate 4L/s |

|

|

Water cooling machine capacity |

10L |

|

|

Core components and functions |

1. Providing a controllable high-temperature reaction environment is the core area for material synthesis, sintering, and annealing.

|

|

|

Carbon monoxide alarm |

Measurement range 0-100% LEL display error ≤± 5% F.S |

|

|

Carbon dioxide alarm device |

Measurement range 0-100% LEL display error ≤± 5% F.S |

|

|

furnace body dimensions |

Length 1080 * Height 1800 * Depth 790mm |

|

|

Furnace weight |

约250KG |

|

|

control system |

|

1. Sintering process curve setting: dynamically display the set curve, and the equipment sintering can pre store multiple process curves, each of which can be freely set;

|

|

heating element |

|

High purity silicon molybdenum rod |

|

temperature accuracy |

±1℃ |

|

|

Net weight |

About 54KG |

|

|

Equipment usage precautions |

When using the equipment, the absolute pressure gauge reading should not exceed 0.15MPa to prevent equipment damage caused by excessive pressure; |

|

|

Service Support |

One year limited warranty with lifetime support (warranty does not include consumable parts such as processing tubes and O-rings, please order replacement at the relevant product below). |

|

推荐产品

Medium vacuum atmosphere pendulum rotary sintering furnace 1200℃

CMT furnace sliding rail tube furnace 1200℃

NBD-LT cold and thermal fatigue testing machine

Vacuum storage cabinet

Liquid vapor phase generator, type Ι

ball mill tank

High vacuum atmosphere muffle furnace

Eight temperature zone rotating inclined tube furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China