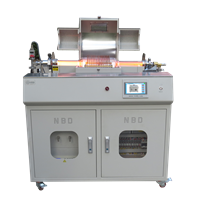

High power PECVD system (Rotary Pendulum Vibration)

Release time: 2020-09-03 15:50:16 Number of views: 2741

Equipment introduction:

Rotary pendulum PECVD system is suitable for thin film deposition on the surface of powder materials. The system is composed of high power RF power supply (500W, 13.56MHz), gas mass flow control system, vacuum system and rotary pendulum system. It adopts Nobardi operating software of NBD-101EP centralized bus control technology. Plasma properties are used to control or influence the process of gas reaction and chemical reaction on the material surface and to deposit thin films at appropriate temperatures. PECVD deposited films have excellent electrical properties, good substrate adhesion and excellent step coverage. Because of these advantages, it has a wide range of applications in VLSI, photoelectric devices, MEMS and other fields.

Configuration

| Main features: | |||

Electrical Spec | AC220V 1.5KW | |||

Equipment dimensions | W1300mm×H1250mm×D760mm; | |||

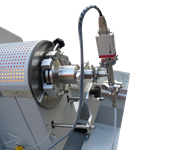

| reaction chamber | L300mm (customizable, welded with three groups of agitation baffles in the pipe), pipe diameter in non-RF area: φ 60mm; | |||

Reverse Speed | R/min (stepless speed regulation); | |||

Tilt over angle |

-Max. dumping angle of 3 ° -+3 ° 30 ° | |||

Pressure of reaction chamber | 5~80pa | |||

Flange structure | Aviation aluminum quick-open mode; | |||

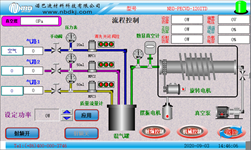

operating system |

NBD-101EP centralized bus control integrated system, 7 "true color touch screen control, intelligent fuzzy PID control; Intelligent man-machine conversation mode; | |||

Power of electric push rod | 50W | |||

RF power supply | Output power of 10-500W is adjustable continuously, RF frequency: 13.56MHz ± 0.005%, fully automatic matching; | |||

Vacuum Test | Digital vacuum gauge acquisition device; | |||

Vacuum acquisition | NBD-4C mechanical vacuum pump (220V/50Hz), power: 0.4KW, pumping speed: 4m³/h; | |||

Air supply system | Air supply system | |||

Equipment details | |

|

| |

Partial interface £¬ PII |

|

|

| |

control system |  | 1. Sintering process curve setting: the setting curve is displayed dynamically, multiple process curves can be pre-stored for equipment sintering, and each process curve can be set freely; 2. Sintering can be reserved to realize unattended sintering process curve sintering; 3. Display sintering power voltage and other information in real time, record sintering data and export paperless records; 4. Remote control and real-time observation of equipment status; 5. Temperature correction: the difference between the main control temperature and the sample temperature, and nonlinear correction shall be carried out throughout the sintering process. | ||

Net weight | 约320KG | |||

Precautions for equipment use |

Generally, the RF matching device is in automatic matching state, and the matching can only be conducted when the power reaches over 50W; | |||

Service support | One year limited warranty with lifetime support; | |||

Disclaimer: the product introduction of the station (including product pictures, product descriptions, technical parameters, etc.) is for reference only. Due to untimely update, there may be some difference between the contents and the actual situation. Please contact our customer service personnel for confirmation. The information provided by this website does not constitute an offer or commitment, and NuCompany will improve and modify any information on the website from time to time without notice.

Related Products

| |||

推荐产品

.png)

MiNi wax removal prefiring furnace

Lift type large capacity sintering furnace

Vertical silent mixing ball mill

NBD-LT cold and thermal fatigue testing machine

Vacuum graphite heating furnace

Production-type atmosphere muffle furnace

Mesh belt brazing furnace

1500 ℃ (80L) ultra large capacity box furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China