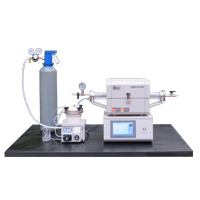

Ultrasonic atomizing CVD tube furnace

Release time: 2020-10-21 14:20:23 Number of views: 3080

Equipment introduction:

This device is an aerosol assisted vapor deposition device-AACVD (using liquid/gas aerosol precursors to grow on the substrate) for fuel cells and ZnO transparent conductive films. This instrument consists of three main modules: micro-flow liquid high-precision transmission system, ultrasonic atomization system, 1200℃ tubular furnace. This technology is suitable for the use of non-volatile precursors, and can be widely used in the preparation of nanomaterials, electrode material coating composite and so on.

Configuration

Features of equipment | 1. Liquid flow control system: intermediate high precision transmission, small flow liquid high precision transmission, flow range: 0.04 ~ 36ml/min; | ||||

Electrical Spec | AC220V 1.2KW | ||||

Tmax | 1200 °C | ||||

Max working temps. | 1100℃ | ||||

Heating rate | ≤ 20 ℃/min | ||||

Heating length | 200mm | ||||

High precision peristaltic pump |

| 1. Speed range: 0.1·100rpm reversible reversible; | |||

atomizer |

| 1.AC220V, 1.7MHz ultrasonic atomizer; | |||

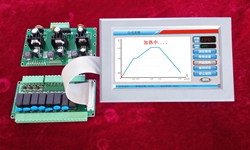

Control system |

| 1. 15 temperature curves can be pre-stored to avoid the trouble caused by repeated setting of different experimental processes; | |||

Temp Accuracy | +/-1 ℃ | ||||

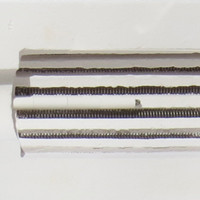

heating element |

| Mo doped Fe Cr Al alloy | |||

Heating element |

| The standard configuration has a float flowmeter with a range of | |||

Net weight | 30KG | ||||

Cautions | 1. When the furnace temperature of the equipment is greater than or equal to 300℃, it is forbidden to open the furnace to avoid injury; 2. When the equipment is in use, the pressure inside the furnace shall not exceed 0.125MPa (absolute pressure) to prevent the pressure from bursting the sealing flange; | ||||

Service | 1 year limited warranty with lifetime support (warranty excludes consumable parts such as handling tubes and O-rings). | ||||

Disclaimer:

The product introduction content of this site (including product pictures, product descriptions, technical parameters, etc.) is for reference only. There may be some difference between the stated content and the actual situation due to the delay in updating. Please contact our customer service staff for confirmation. The information provided by this Site does not constitute any offer or acceptance. NOBODY will improve and modify any information on this site from time to time without prior notice.

Related products

|

|

|

|

|

|

|

|

推荐产品

CVD system O1200-XTID3F

Thermogravimetric analysis (TGA) and condensation collection systems

Anaerobic hot dip plating (quenching) system

System O1200-XT22D2F

Multichannel gas automatic controller

Mini vacuum furnace for glove box

Split pit furnace for glove box

1500℃ large capacity muffle furnace

- {{item.cat}}

- {{item2.cat}}

- {{ isExpanded[index2] ? 'Retract' : 'More' }}

Phone: 400-000-3746

0371-6320 2805

After-sales service: 0371-6320 2805

MR. CAI: 181-0371-5723

Mr.Gao: 188-3829-0747

Ms.Huang: 188-3829-0748

Email : nbd@nbdkj.com

Address:8# zhuyuan, Xinhua subdistrict, Xinzheng, Zhengzhou, China